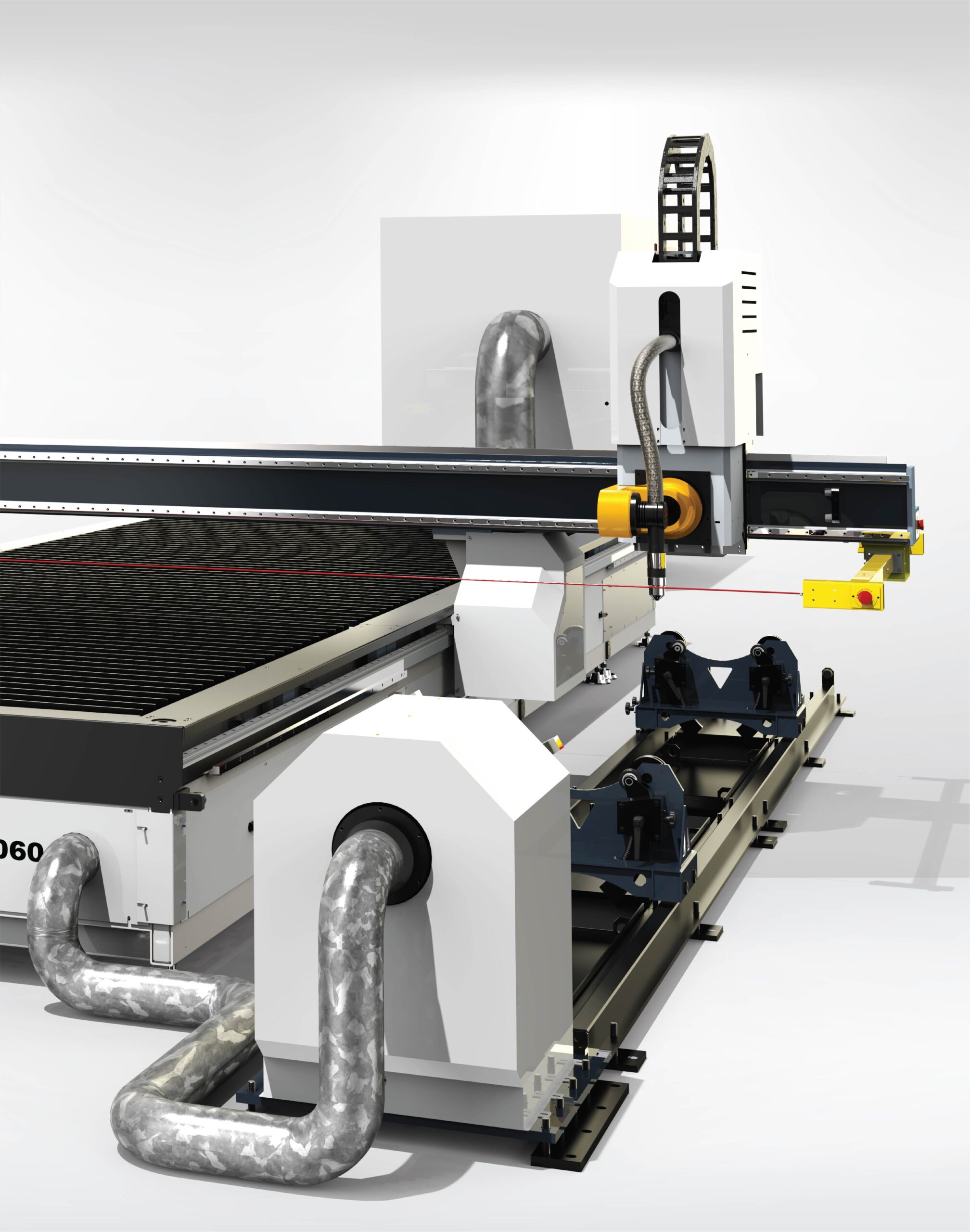

Durma PL-C (Compact) Series Plasma Cutting Machine has a modular frame. Modular frames are welded, and stress relief is performed after welding to ensure quality and accuracy. High-quality and precise plasma cutting is possible with double-sided synchronized gap-free planetary reducers that offer high precision. High positioning speed, acceleration, and automatic torch height control ensure the best cutting quality for your manufacturing needs. The tables are fragmented and divided for the effective evacuation of smoke that might occur during the cutting processes. Manual and automatic bevel cutting, drilling station, and oxygen cutting heads are some of the available optional features. We as Durma know that you have differing needs, and we provide precise solutions to your manufacturing problems with our innovative and dedicated team.

Durma has redefined its plasma cutting technology with PL-C series. The PL-C Series is manufactured as a true precision tool for plasma cutting. Our high-performance plasma machines are designed to cut a wide range of mild steel, stainless steel and aluminum. They offer:

Durma PL-C offers better, faster and more precise cuts. It has a strong and rigid body structure. The PLC Plasma Cutting machine is a durable machine, and it will be by your side for long and productive years. It is a plasma that you can count on. “Reliability and durability” that what makes a the Durma PL-C Plasma Cutting Machine

PLC Plasma cutting machines are reliable sources of plasma cuttings when it comes to higher levels of material thickness. Hypertherm cutting head and AURORA plasma software ensure precise and quality cuts. The AURORA software enables users to enhance plasma with extensive specifications and capabilities. Depending on material and thickness, cut quality and cutting speed it can offer you the appropriate solutions for your tasks.

It has a sensitive, precise Hypertherm cutting head. Moreover, it has the Durma designed and copyrighted AURORA software control unit. The Hypertherm power supply options for different sheet thicknesses. Furthermore, Electrical Panel and Durma Filter that creates a safer working environment. It offers sensitive solutions at high material thickness. PLC is environmentally friendly and energy efficient.

PL-C Series Standard Equipment comes with:

Steel Construction: Strengthened steel body structure increases DURMA plasma’s durability and performance.

Plasma Cutting Head: which is designed for fast cutting speeds, long life and superior cut quality for high productivity and low operating costs. It delivers superior performance cutting across a broad range of application needs, from very thin to heavier thickness.

Durma Control Unit: PLC series come with standard DURMA control unit that provides convenient user experience. Users can realize tasks on plasma efficiently with a user-friendly control unit.

Plasma Power Source: Plasma power source combines fast cutting speeds, rapid process cycling, quick changeovers and high reliability to maximize productivity. Key advantages are new HDi thin stainless-steel technology, superior cut quality and consistency, maximized productivity, minimized operating cost and unmatched reliability.

Business, like life, is a journey. With Durma machines, you will overcome all obstacles and surmount all challenges that business presents. We will be with you every step of the way. We know that your growth is our growth, and that your success is our success. As Durma, we manufacture machines that are durable, flexible and innovative. We aim for excellence in all our machines, and we build trust with our customers to produce flawless tools. Our cutting-edge technology will get you clear-cut results, fast, with perfection.

Durma, means ‘Keep going’. With Durma you will progress and produce continuously.